Application Scenarios

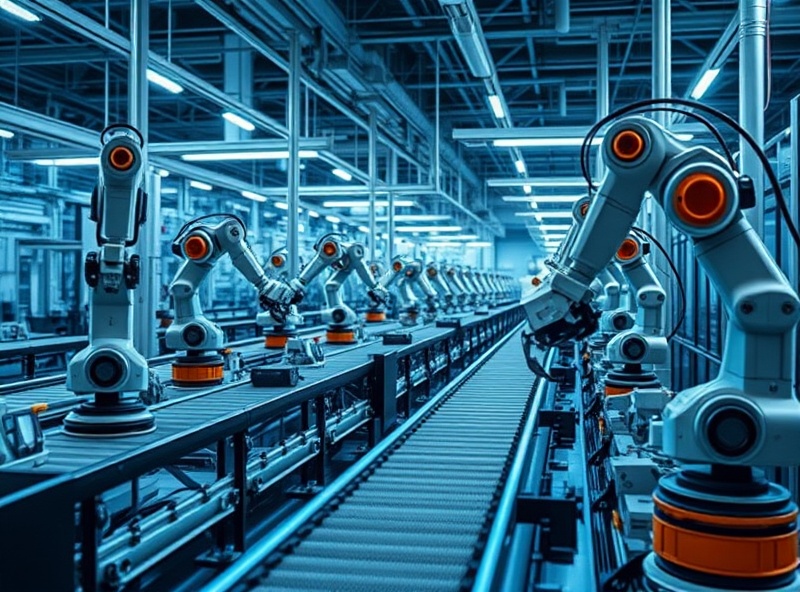

Versatile Solutions Across Industries

Product Center

Comprehensive portfolio covering 3 core technology verticals

Why Choose DZGU

Quality Assurance

Our CNAS-certified laboratory employs AI-powered optical inspection systems and automated continuity testers, ensuring 99.97% product reliability across 150+ quality checkpoints. Every connector undergoes 36-hour accelerated aging tests before shipment.

Cooperation Process

Streamlined workflow from concept to delivery

Certifications

Internationally recognized compliance credentials

Client Testimonials

Global partners share their collaboration experience